What Is Value Engineering in Construction? 6-Step Process

Learn what is value engineering in construction and use our 6-step process to reduce costs without sacrificing quality. See real-world bridge examples.

What Is Value Engineering in Construction? 6-Step Process

A bridge project comes in $2 million over budget. The design meets every code requirement, but the owner wants alternatives. This is where understanding what is value engineering in construction becomes essential, it's the structured method teams use to cut costs without sacrificing function or safety.

Value engineering isn't about cheapening a project. It's about systematically questioning every design decision to find smarter solutions that deliver the same (or better) performance at lower cost. For bridge contractors and structural engineers, this process can mean the difference between winning a bid and watching it go to a competitor.

This article breaks down the six-step value engineering process, shows how it applies to real construction scenarios, and explains why modern engineering platforms like Arched are automating what used to take weeks of manual analysis. By the end, you'll have a clear framework for identifying value engineering opportunities on your next infrastructure project.

Value engineering vs cost cutting

Most project teams confuse these two approaches, but the distinction matters. Cost cutting means removing features or downgrading materials to hit a budget target, often at the expense of long-term performance. Value engineering asks a different question: can you achieve the same result through a smarter design approach? When you understand what is value engineering in construction, you realize it's about improving the cost-to-value ratio, not just slashing line items.

What cost cutting actually removes

Traditional cost cutting targets the most expensive components first. You might switch from steel beams to lighter alternatives without analyzing load distribution, or eliminate protective coatings to save $50,000 upfront. These decisions create technical debt that surfaces during construction or decades into a structure's service life. The project gets cheaper on paper, but you've removed functional capacity or durability that the original design required.

Cost cutting asks "what can we eliminate?" while value engineering asks "what can we improve?"

What value engineering preserves

Value engineering maintains every performance requirement while finding better ways to meet them. Instead of removing a bridge's protective coating, you might reconfigure the steel sections to reduce exposed surface area by 15%. The bridge still meets the same corrosion resistance standards, but you've cut material costs without touching the coating budget. You're redesigning around the constraint rather than ignoring it. This approach requires deeper analysis, which is why many teams default to simple cost cutting when deadlines tighten. Modern simulation tools now automate this analysis, testing thousands of design variations to find legitimate savings that preserve all functional requirements.

When to use value engineering

You trigger value engineering at specific moments in a project's lifecycle, not as a continuous process running from day one. The most common trigger is cost overrun, when initial estimates exceed the approved budget by 10% or more. Teams also initiate the process when regulatory changes force expensive design modifications, or when material supply constraints make the original specification impossible to execute within schedule.

Early design phase opportunities

The best time to apply value engineering is during schematic or preliminary design, before you've finalized details that lock in costs. At this stage, you can still adjust fundamental decisions like structural systems, foundation types, or span configurations without triggering expensive redesign work. Waiting until construction documents are 90% complete means most alternatives will require throwing away weeks of engineering hours, which offsets any savings you might achieve.

Value engineering works best when you still have design flexibility, not when drawings are ready for bid.

Budget crisis situations

Projects facing immediate funding cuts benefit most from understanding what is value engineering in construction. When a DOT reduces allocated capital by $3 million mid-project, you need systematic alternatives rather than random cost reductions. Value engineering gives you a defendable framework to present options that maintain safety standards while meeting the new financial reality.

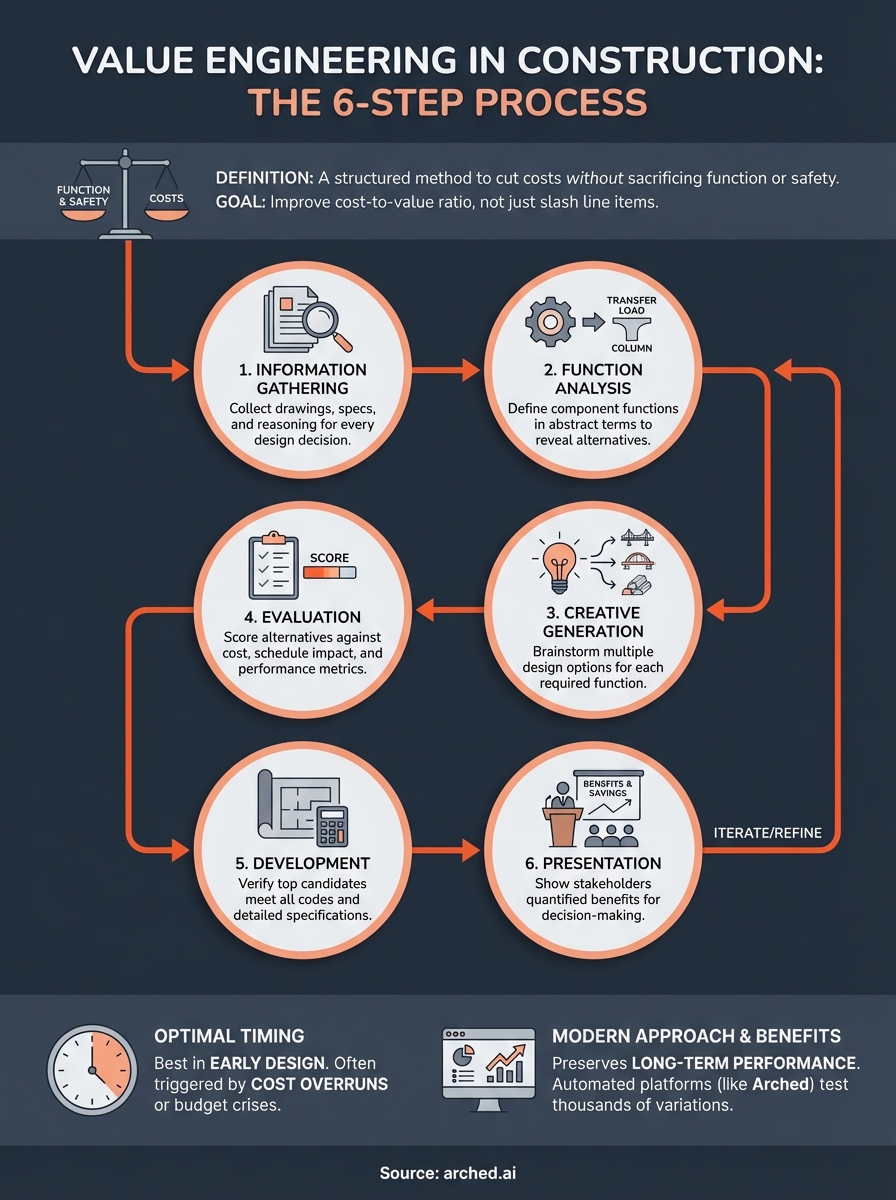

The six-step value engineering process

The formal methodology follows six distinct phases that teams apply regardless of project type or scale. You start by gathering information about the current design, then systematically work through function analysis, creative generation, evaluation, development, and presentation. This structured approach prevents the random brainstorming that often leads to impractical suggestions or features that compromise safety standards.

Information and function analysis

Your first task involves documenting every design decision and its cost. You collect drawings, specifications, and the reasoning behind each choice. Next, you define what each component must accomplish in functional terms rather than physical descriptions. A bridge pier isn't just "concrete column," it becomes "transfer vertical loads" and "resist lateral forces." This abstraction reveals alternative solutions that meet the same functional requirements.

Function analysis forces you to separate what components must do from how they currently do it.

Creative alternatives and evaluation

Once you understand functions, you generate multiple design options that could satisfy each requirement. Your team scores every alternative against cost, schedule impact, and performance metrics. The top candidates move into detailed development where you verify they meet all codes and specifications. Final presentations show owners the quantified benefits of each recommended change, letting them choose which alternatives to implement based on their priorities.

Practical examples for buildings and bridges

Real projects demonstrate what is value engineering in construction better than theory alone. Commercial buildings often achieve 8-12% cost reductions by analyzing structural bay spacing, while bridge projects can save $500,000 or more through optimized beam configurations that use less steel without compromising load capacity.

Building optimization scenarios

Your team reviews a five-story office building designed with 30-foot bay spacing and discovers that adjusting to 32 feet eliminates an entire column line. This change reduces foundation work by 15% and cuts the structural steel budget by $180,000. The floor system needs slightly deeper beams to span the longer distance, but total project costs drop by $140,000 after accounting for the increased beam depth.

Structural bay spacing changes can eliminate entire rows of columns and foundations without reducing floor capacity.

Bridge design alternatives

A highway overpass originally specified eight 60-foot spans with constant-depth steel plate girders. Analysis reveals that switching to three longer spans with variable-depth girders eliminates five piers, cutting foundation costs by $420,000. Construction duration drops from 14 months to 11 months because you're building fewer substructures. The girders cost more per ton, but overall project savings exceed $380,000 while maintaining the same load rating.

Common pitfalls and how to avoid them

Teams fail at value engineering when they focus exclusively on initial construction costs without considering lifecycle impacts. Your analysis might show that switching to cheaper concrete saves $80,000 upfront, but if it requires replacement in 25 years instead of 40, you've created a long-term financial burden. Another common mistake is rushing the evaluation phase to meet tight deadlines, which leads to recommendations that look good on paper but fail during detailed design development.

Focusing only on first costs

Initial budget savings often hide expensive maintenance requirements or shortened service life. You need to calculate total ownership costs over the structure's design life, not just what it takes to build. A protective coating system might add $120,000 to construction costs but eliminate $600,000 in repair work over 30 years. Lifecycle analysis reveals the true value of design decisions.

Short-term savings often create long-term expenses that exceed any initial budget reductions.

Skipping performance validation

Recommendations fail when teams skip detailed verification that alternatives meet all code requirements and performance standards. You must confirm each proposed change through structural analysis, not assumptions. Understanding what is value engineering in construction means proving that every alternative delivers the required function before presenting it to stakeholders.

Final thoughts

Understanding what is value engineering in construction gives you a competitive advantage that goes beyond simple cost reduction. You now have a structured framework for analyzing every design decision against function, cost, and performance criteria. The six-step process transforms budget pressures into opportunities to discover smarter solutions that your competitors miss.

The most successful teams don't wait for crisis moments to apply these principles. They integrate value engineering thinking into early design phases where changes cost less and deliver greater impact. Modern platforms are now automating the analysis that used to require weeks of manual calculation, running thousands of design variations to identify the optimal balance between cost, durability, and constructability.

Bridge projects benefit especially from this automated approach. Arched AI applies generative engineering to explore design alternatives that meet all AASHTO standards while quantifying cost savings and carbon reductions, turning value engineering from a manual exercise into a data-driven competitive edge.